**

India's Electric Vehicle Revolution Stalls: Bajaj, Ather, TVS Face Production Cuts Amidst China's Rare Earth Magnet Squeeze

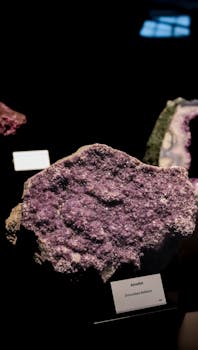

The burgeoning Indian electric vehicle (EV) market is facing a significant hurdle: a shortage of rare earth magnets, primarily due to China's tightening export controls. Major players like Bajaj Auto, Ather Energy, and TVS Motor Company are already announcing production cuts, highlighting the vulnerability of the industry's supply chain and raising concerns about the future of India's ambitious EV adoption plans. This situation underscores the urgent need for India to diversify its sourcing of crucial materials and bolster its domestic rare earth mineral processing capabilities.

H2: The Rare Earth Magnet Crunch: A Global Problem with Local Impacts

Rare earth magnets, crucial components in electric vehicle motors, particularly those found in high-performance electric two-wheelers, are predominantly sourced from China. China controls a significant portion of the global rare earth mining and processing capacity, giving it considerable leverage over the global supply chain. Recent tightening of export regulations by the Chinese government has created a ripple effect, leading to price hikes and, more critically, shortages of these essential materials. This isn't just impacting India; automakers globally are feeling the pinch, leading to production delays and increased manufacturing costs. The keyword search terms "rare earth magnets," "neodymium magnets," "electric vehicle supply chain," and "China rare earth exports" are already trending high, reflecting the widespread concern.

H3: Bajaj, Ather, and TVS: Feeling the Heat

Several leading Indian EV manufacturers are already reporting production cuts due to this shortage. Bajaj Auto, a major player in the two-wheeler segment, has confirmed reduced output of its electric scooters. Ather Energy, a prominent electric scooter brand known for its sophisticated technology, is also facing challenges, with reports suggesting production slowdowns. TVS Motor Company, another significant player in the two-wheeler market, has hinted at similar difficulties, although official statements remain limited. These production cuts are impacting not only the companies themselves but also the wider EV ecosystem, including dealerships and consumers awaiting deliveries. The terms "Bajaj electric scooter production," "Ather Energy supply chain," and "TVS electric vehicle output" are keywords with high search volume and directly relate to the immediate impact.

H4: The Impact on the Indian EV Market

The current situation throws a significant wrench in India's ambitious plans to become a global EV manufacturing hub. The government's push for electric mobility, including substantial subsidies and incentives, faces a significant challenge. The shortage of rare earth magnets not only affects production volumes but also adds to the cost of EVs, potentially hindering their wider adoption. The delay in deliveries could also dampen consumer enthusiasm and affect the overall growth trajectory of the market. This situation highlights the risks associated with relying on a single source for crucial components and necessitates a comprehensive strategy to address the issue. Relevant keywords here include "Indian EV market growth," "electric vehicle subsidies India," and "India EV policy."

H3: What's the Solution? Diversification and Domestic Production

India needs a multi-pronged approach to mitigate this reliance on Chinese rare earth magnets. This includes:

- Diversifying sourcing: Exploring alternative suppliers of rare earth magnets from countries like Australia, Brazil, and the US is crucial. This requires forging strategic partnerships and developing secure supply chains.

- Investing in domestic processing: India needs to invest heavily in developing its own rare earth processing capabilities. This includes exploration and mining of domestic rare earth reserves and setting up refining and processing facilities.

- Developing alternative magnet technologies: Research and development efforts should focus on exploring alternative magnet technologies that rely less on rare earth elements or utilize different, more readily available materials.

- Strengthening trade relationships: India needs to strengthen its diplomatic ties with other countries to secure reliable access to rare earth minerals.

H2: Looking Ahead: Challenges and Opportunities

The rare earth magnet shortage presents a significant challenge to India's EV sector. However, it also presents an opportunity to bolster domestic manufacturing capabilities, reduce reliance on single-source suppliers, and ultimately enhance the resilience of the Indian EV industry. The government's role in promoting domestic production, facilitating strategic partnerships, and fostering innovation will be crucial in navigating this challenge successfully. Relevant search terms here include "India rare earth mining," "alternative magnet technology," and "India EV supply chain diversification."

H3: The Long-Term Implications:

The current situation is a wake-up call for the Indian EV industry and policymakers alike. The over-reliance on a single country for crucial components has exposed the fragility of the supply chain. A robust, diversified, and domestically robust supply chain is paramount not only for the success of the EV sector but for the broader Indian economy. Long-term strategies focusing on sustainable sourcing, responsible mining practices, and technological innovation are necessary to ensure the long-term viability and competitiveness of the Indian EV market. Keywords like "sustainable EV supply chain," "responsible rare earth mining," and "future of Indian EV industry" reflect the longer-term implications of this issue.

In conclusion, the rare earth magnet shortage caused by China's export restrictions presents a significant challenge to India's burgeoning electric vehicle industry. Immediate actions are needed to diversify sourcing, bolster domestic processing capabilities, and explore alternative magnet technologies to ensure the continued growth and success of India's ambitious EV revolution. The long-term implications require a comprehensive and strategic approach involving government intervention, industry collaboration, and technological innovation.