Key Insights

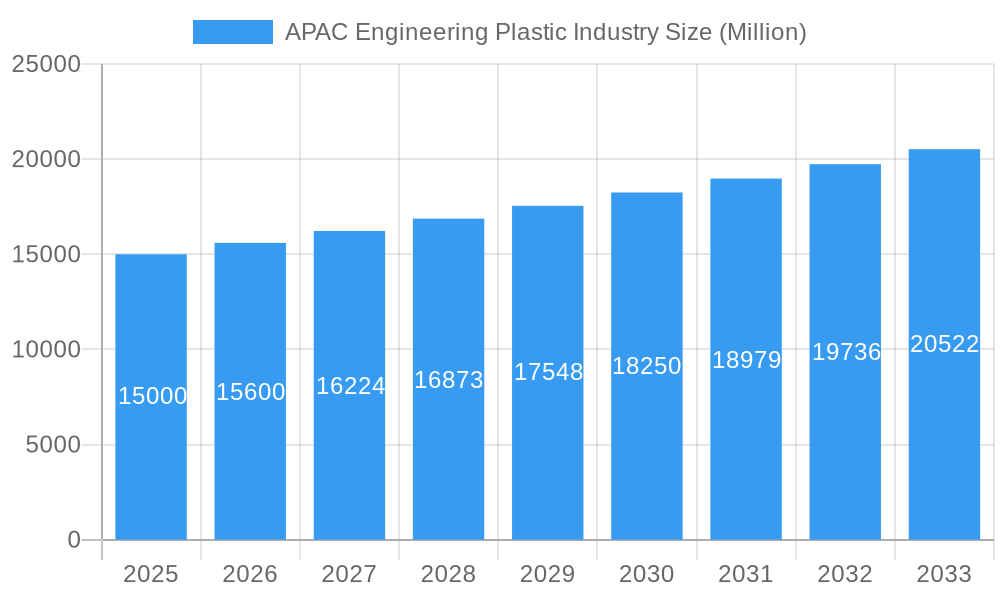

The Asia-Pacific (APAC) engineering plastics market is experiencing robust growth, driven by the region's expanding automotive, electronics, and construction sectors. A compound annual growth rate (CAGR) exceeding 4% indicates a significant upward trajectory, with the market size projected to reach substantial value in the coming years. Key drivers include increasing demand for lightweight and high-performance materials in vehicles, the proliferation of electronic devices, and the growth of infrastructure development across major APAC economies like China, India, and Japan. The rising adoption of electric vehicles (EVs) further fuels demand, as engineering plastics are crucial components in EV batteries and other crucial parts. While supply chain disruptions and fluctuations in raw material prices present some challenges, the overall market outlook remains positive. Specific resin types such as polybutylene terephthalate (PBT), polycarbonate (PC), and polyether ether ketone (PEEK) are experiencing particularly strong growth due to their superior properties, including heat resistance, durability, and chemical resistance. The segmentation by end-user industry highlights the significant contribution of the automotive and electronics sectors, underscoring the market's close ties to technological advancements and industrial production. Furthermore, ongoing innovations in material science and the development of more sustainable engineering plastics are expected to contribute to the market's sustained expansion.

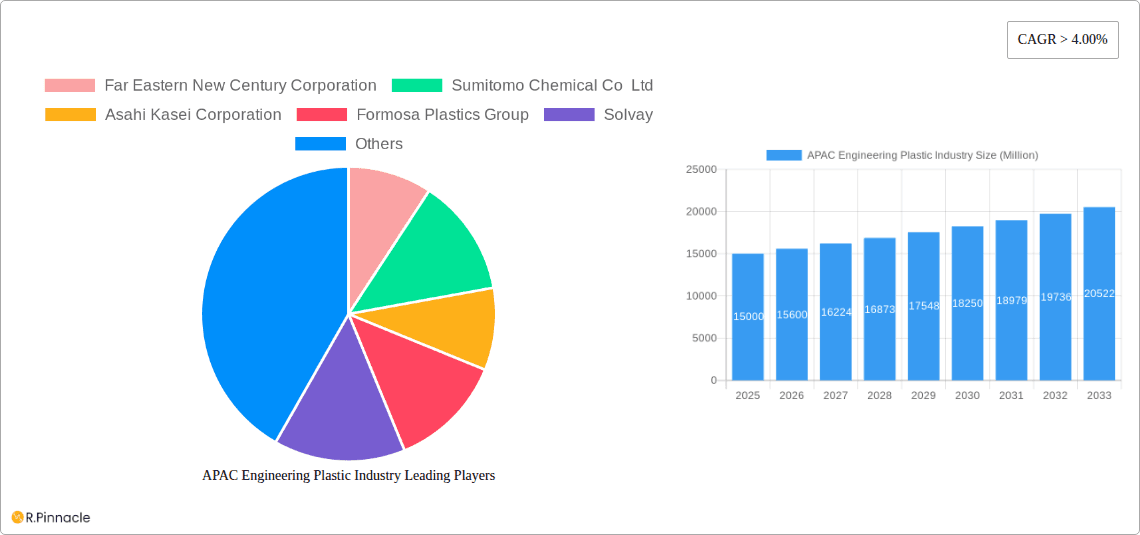

APAC Engineering Plastic Industry Market Size (In Billion)

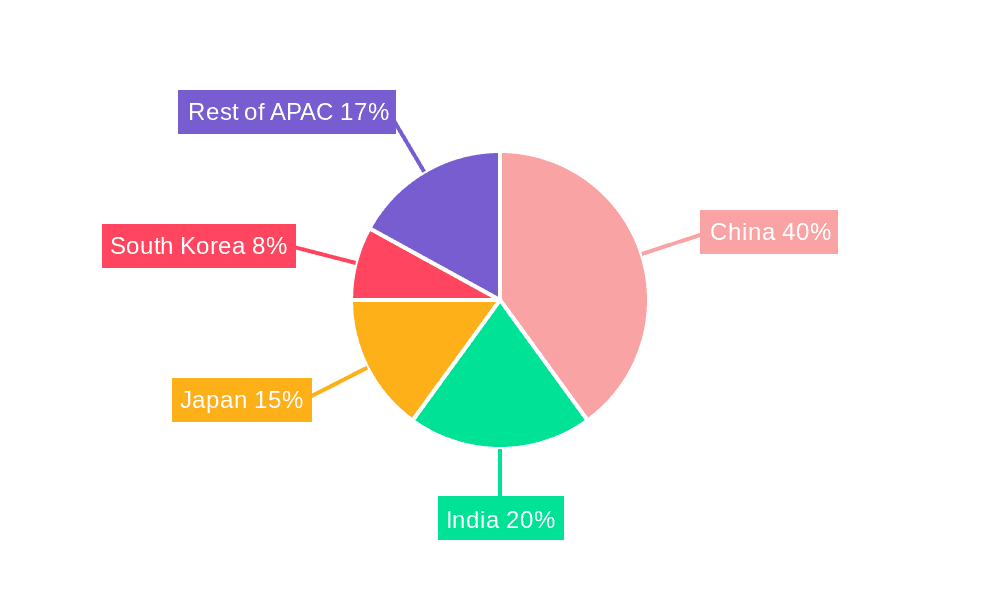

The market's geographical distribution shows that China, India, and Japan are leading consumers, reflecting their advanced manufacturing capabilities and large consumer bases. However, other countries in the region are also witnessing significant growth, particularly those undergoing rapid industrialization. The competitive landscape features both global and regional players, with established manufacturers continually investing in research and development to enhance product offerings and expand market share. Competition is intense, requiring manufacturers to focus on innovation, cost-effectiveness, and strong supply chain management to gain a competitive edge. The forecast period (2025-2033) promises continued expansion, driven by sustained economic growth, technological progress, and governmental support for infrastructural development throughout the APAC region. The market's resilience to global economic fluctuations and its continued growth potential make it an attractive sector for investment and further development.

APAC Engineering Plastic Industry Company Market Share

APAC Engineering Plastics Industry Report: 2019-2033

This comprehensive report provides an in-depth analysis of the Asia-Pacific engineering plastics market, offering invaluable insights for industry professionals, investors, and strategic planners. Covering the period 2019-2033, with a focus on 2025, this report unveils market dynamics, growth drivers, competitive landscapes, and future trends across diverse segments. The report projects a market size exceeding xx Million by 2033, presenting a compelling growth opportunity.

APAC Engineering Plastic Industry Market Structure & Innovation Trends

This section analyzes the competitive landscape of the APAC engineering plastics market, encompassing market concentration, innovation drivers, regulatory frameworks, product substitutes, end-user demographics, and merger & acquisition (M&A) activities. The market is characterized by a mix of large multinational corporations and regional players. Key players like Far Eastern New Century Corporation, Sumitomo Chemical Co Ltd, Asahi Kasei Corporation, Formosa Plastics Group, Solvay, Mitsubishi Chemical Corporation, Toray Industries Inc, CHIMEI, China Petroleum & Chemical Corporation, Lotte Chemical, LG Chem, Sinochem, Covestro AG, China Resources (Holdings) Co Ltd, and Sanfame Group hold significant market share, with the top 5 players collectively accounting for approximately xx% of the market in 2024.

- Market Concentration: Highly concentrated at the top, with significant regional variations.

- Innovation Drivers: Growing demand for lightweight, high-performance materials across various end-user industries. Advancements in additive manufacturing (3D printing) are also driving innovation.

- Regulatory Frameworks: Stringent environmental regulations are pushing for sustainable and recyclable solutions.

- Product Substitutes: Bio-based plastics and other advanced materials pose a competitive threat.

- End-User Demographics: The increasing demand from the automotive, electronics, and packaging industries is a significant growth factor.

- M&A Activities: The past five years have witnessed xx Million in M&A deals, primarily focused on expanding market access and product portfolios. Deal values are expected to increase to xx Million by 2033.

APAC Engineering Plastic Industry Market Dynamics & Trends

This section delves into the factors shaping the APAC engineering plastics market's trajectory. Market growth is driven by robust economic growth across the region, particularly in China and India, coupled with increasing demand for durable, high-performance materials in diverse end-use sectors. The automotive industry, spurred by electric vehicle adoption, remains a major driver, alongside the electronics sector's continuous advancements. Technological disruptions, such as the rise of 3D printing and the development of sustainable materials, are significantly impacting market dynamics. Consumer preference for lighter, more efficient products is pushing the adoption of advanced engineering plastics. The market exhibits intense competition, with companies constantly innovating to gain a competitive edge. The CAGR for the forecast period (2025-2033) is estimated at xx%. Market penetration of specific engineering plastics like PBT and PC in key end-user sectors is expected to increase to xx% and xx%, respectively, by 2033.

Dominant Regions & Segments in APAP Engineering Plastic Industry

China is the dominant region in the APAC engineering plastics market, accounting for over xx% of the total market in 2024, driven by its massive manufacturing base and rapid industrialization. India and South Korea also contribute significantly. Among segments, Polybutylene Terephthalate (PBT) and Polycarbonate (PC) are the leading resin types, witnessing high demand across various applications.

Key Drivers:

- Economic Growth: Strong economic growth in China and India fuels demand.

- Infrastructure Development: Expansion of infrastructure projects necessitates increased material usage.

- Government Policies: Supportive government policies promoting industrial growth.

Dominance Analysis: China's robust manufacturing sector, coupled with supportive government policies fostering industrial growth and infrastructure development, makes it the dominant player in the APAC engineering plastics market. India's growing economy and increasing manufacturing activities are propelling its market share growth. South Korea's advanced technological capabilities and focus on high-value-added products position it as a key regional player.

APAC Engineering Plastic Industry Product Innovations

Recent innovations include Covestro AG's Makrolon 3638 polycarbonate for healthcare and life sciences, and Toray Industries Inc.'s Toraypearl PA6 for 3D printing. These developments reflect the industry's focus on specialized applications and sustainable solutions. The trend leans toward high-performance materials with enhanced properties like heat resistance, strength, and biodegradability, meeting the demands of evolving industrial applications.

Report Scope & Segmentation Analysis

This report segments the APAC engineering plastics market by resin type (Polyphthalamide, PBT, PC, PEEK, PET, PI, PMMA, POM, ABS & SAN, Fluoropolymer), country (Australia, China, India, Japan, Malaysia, South Korea, Rest of Asia-Pacific), and end-user industry (Aerospace, Automotive, Building & Construction, Electrical & Electronics, Industrial & Machinery, Packaging, Other). Each segment's growth projections, market size, and competitive dynamics are analyzed, providing a detailed understanding of the market's structure and evolution. For example, the Polycarbonate segment is projected to grow at a CAGR of xx% during the forecast period driven by demand from the automotive and electronics sectors.

Key Drivers of APAC Engineering Plastic Industry Growth

The APAC engineering plastics market's growth is driven by several factors. Firstly, the region's burgeoning economies fuel demand for various products requiring engineering plastics. Secondly, rapid industrialization necessitates a robust supply of high-performance materials. Thirdly, technological advancements, particularly in 3D printing and sustainable materials, are creating new opportunities. Finally, supportive government policies and investments in infrastructure projects further bolster growth.

Challenges in the APAP Engineering Plastic Industry Sector

The APAC engineering plastics industry faces challenges such as fluctuating raw material prices, impacting production costs and profitability. Supply chain disruptions also pose a significant threat, especially in the context of geopolitical uncertainty. Furthermore, intense competition among established players and emerging businesses creates pressure on margins. Environmental regulations require manufacturers to adopt sustainable production practices and develop eco-friendly materials, adding to operational complexities. These challenges, if not addressed effectively, could dampen market growth by xx% in the worst-case scenario.

Emerging Opportunities in APAC Engineering Plastic Industry

Emerging trends include the growing demand for lightweight, high-strength materials in electric vehicles, the increasing adoption of 3D printing in various industries, and the focus on sustainable and recyclable plastics. These factors unlock opportunities for innovation and market expansion. Further, the penetration of engineering plastics into niche applications such as medical devices and renewable energy offers substantial potential for growth.

Leading Players in the APAC Engineering Plastic Industry Market

- Far Eastern New Century Corporation

- Sumitomo Chemical Co Ltd

- Asahi Kasei Corporation

- Formosa Plastics Group

- Solvay

- Mitsubishi Chemical Corporation

- Toray Industries Inc

- CHIMEI

- China Petroleum & Chemical Corporation

- Lotte Chemical

- LG Chem

- Sinochem

- Covestro AG

- China Resources (Holdings) Co Ltd

- Sanfame Group

Key Developments in APAC Engineering Plastic Industry Industry

- August 2022: Toray Industries Inc. launched Toraypearl PA6, a high-strength, heat-resistant material for 3D printing, expanding applications in advanced manufacturing.

- August 2022: Covestro AG announced a new mechanical recycling line in Shanghai, highlighting a commitment to sustainable practices and circular economy initiatives within the industry.

- February 2023: Covestro AG introduced Makrolon 3638 polycarbonate, targeting healthcare and life sciences applications, signifying growth in specialized material segments.

Future Outlook for APAC Engineering Plastic Industry Market

The APAC engineering plastics market is poised for robust growth, fueled by ongoing industrialization, technological advancements, and increasing demand for high-performance materials across various sectors. Strategic investments in research and development, coupled with a focus on sustainable solutions, will play a crucial role in shaping the market's future. The market is expected to witness significant expansion, driven by emerging applications in electric vehicles, 3D printing, and healthcare, along with increased focus on circular economy solutions.

APAC Engineering Plastic Industry Segmentation

-

1. End User Industry

- 1.1. Aerospace

- 1.2. Automotive

- 1.3. Building and Construction

- 1.4. Electrical and Electronics

- 1.5. Industrial and Machinery

- 1.6. Packaging

- 1.7. Other End-user Industries

-

2. Resin Type

-

2.1. Fluoropolymer

-

2.1.1. By Sub Resin Type

- 2.1.1.1. Ethylenetetrafluoroethylene (ETFE)

- 2.1.1.2. Fluorinated Ethylene-propylene (FEP)

- 2.1.1.3. Polytetrafluoroethylene (PTFE)

- 2.1.1.4. Polyvinylfluoride (PVF)

- 2.1.1.5. Polyvinylidene Fluoride (PVDF)

- 2.1.1.6. Other Sub Resin Types

-

2.1.1. By Sub Resin Type

- 2.2. Liquid Crystal Polymer (LCP)

-

2.3. Polyamide (PA)

- 2.3.1. Aramid

- 2.3.2. Polyamide (PA) 6

- 2.3.3. Polyamide (PA) 66

- 2.3.4. Polyphthalamide

- 2.4. Polybutylene Terephthalate (PBT)

- 2.5. Polycarbonate (PC)

- 2.6. Polyether Ether Ketone (PEEK)

- 2.7. Polyethylene Terephthalate (PET)

- 2.8. Polyimide (PI)

- 2.9. Polymethyl Methacrylate (PMMA)

- 2.10. Polyoxymethylene (POM)

- 2.11. Styrene Copolymers (ABS and SAN)

-

2.1. Fluoropolymer

APAC Engineering Plastic Industry Segmentation By Geography

-

1. Asia Pacific

- 1.1. China

- 1.2. India

- 1.3. Japan

- 1.4. South Korea

- 1.5. ASEAN

- 1.6. Oceania

- 1.7. Rest of Asia Pacific

APAC Engineering Plastic Industry Regional Market Share

Geographic Coverage of APAC Engineering Plastic Industry

APAC Engineering Plastic Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 4.6% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Huge Growth in the Polyurethane Foam Application; Increasing Demand from the Construction Industry

- 3.3. Market Restrains

- 3.3.1. Shortage and Increased Price of Raw Material; Other Restraints

- 3.4. Market Trends

- 3.4.1. OTHER KEY INDUSTRY TRENDS COVERED IN THE REPORT

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. APAC Engineering Plastic Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by End User Industry

- 5.1.1. Aerospace

- 5.1.2. Automotive

- 5.1.3. Building and Construction

- 5.1.4. Electrical and Electronics

- 5.1.5. Industrial and Machinery

- 5.1.6. Packaging

- 5.1.7. Other End-user Industries

- 5.2. Market Analysis, Insights and Forecast - by Resin Type

- 5.2.1. Fluoropolymer

- 5.2.1.1. By Sub Resin Type

- 5.2.1.1.1. Ethylenetetrafluoroethylene (ETFE)

- 5.2.1.1.2. Fluorinated Ethylene-propylene (FEP)

- 5.2.1.1.3. Polytetrafluoroethylene (PTFE)

- 5.2.1.1.4. Polyvinylfluoride (PVF)

- 5.2.1.1.5. Polyvinylidene Fluoride (PVDF)

- 5.2.1.1.6. Other Sub Resin Types

- 5.2.1.1. By Sub Resin Type

- 5.2.2. Liquid Crystal Polymer (LCP)

- 5.2.3. Polyamide (PA)

- 5.2.3.1. Aramid

- 5.2.3.2. Polyamide (PA) 6

- 5.2.3.3. Polyamide (PA) 66

- 5.2.3.4. Polyphthalamide

- 5.2.4. Polybutylene Terephthalate (PBT)

- 5.2.5. Polycarbonate (PC)

- 5.2.6. Polyether Ether Ketone (PEEK)

- 5.2.7. Polyethylene Terephthalate (PET)

- 5.2.8. Polyimide (PI)

- 5.2.9. Polymethyl Methacrylate (PMMA)

- 5.2.10. Polyoxymethylene (POM)

- 5.2.11. Styrene Copolymers (ABS and SAN)

- 5.2.1. Fluoropolymer

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by End User Industry

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 Far Eastern New Century Corporation

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Sumitomo Chemical Co Ltd

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Asahi Kasei Corporation

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Formosa Plastics Group

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 Solvay

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Mitsubishi Chemical Corporation

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Toray Industries Inc

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 CHIMEI

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 China Petroleum & Chemical Corporation

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Lotte Chemical

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 LG Chem

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Sinochem

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.13 Covestro AG

- 6.2.13.1. Overview

- 6.2.13.2. Products

- 6.2.13.3. SWOT Analysis

- 6.2.13.4. Recent Developments

- 6.2.13.5. Financials (Based on Availability)

- 6.2.14 China Resources (Holdings) Co Ltd

- 6.2.14.1. Overview

- 6.2.14.2. Products

- 6.2.14.3. SWOT Analysis

- 6.2.14.4. Recent Developments

- 6.2.14.5. Financials (Based on Availability)

- 6.2.15 Sanfame Group

- 6.2.15.1. Overview

- 6.2.15.2. Products

- 6.2.15.3. SWOT Analysis

- 6.2.15.4. Recent Developments

- 6.2.15.5. Financials (Based on Availability)

- 6.2.1 Far Eastern New Century Corporation

List of Figures

- Figure 1: APAC Engineering Plastic Industry Revenue Breakdown (undefined, %) by Product 2025 & 2033

- Figure 2: APAC Engineering Plastic Industry Share (%) by Company 2025

List of Tables

- Table 1: APAC Engineering Plastic Industry Revenue undefined Forecast, by End User Industry 2020 & 2033

- Table 2: APAC Engineering Plastic Industry Volume K Tons Forecast, by End User Industry 2020 & 2033

- Table 3: APAC Engineering Plastic Industry Revenue undefined Forecast, by Resin Type 2020 & 2033

- Table 4: APAC Engineering Plastic Industry Volume K Tons Forecast, by Resin Type 2020 & 2033

- Table 5: APAC Engineering Plastic Industry Revenue undefined Forecast, by Region 2020 & 2033

- Table 6: APAC Engineering Plastic Industry Volume K Tons Forecast, by Region 2020 & 2033

- Table 7: APAC Engineering Plastic Industry Revenue undefined Forecast, by End User Industry 2020 & 2033

- Table 8: APAC Engineering Plastic Industry Volume K Tons Forecast, by End User Industry 2020 & 2033

- Table 9: APAC Engineering Plastic Industry Revenue undefined Forecast, by Resin Type 2020 & 2033

- Table 10: APAC Engineering Plastic Industry Volume K Tons Forecast, by Resin Type 2020 & 2033

- Table 11: APAC Engineering Plastic Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 12: APAC Engineering Plastic Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 13: China APAC Engineering Plastic Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 14: China APAC Engineering Plastic Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 15: India APAC Engineering Plastic Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 16: India APAC Engineering Plastic Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 17: Japan APAC Engineering Plastic Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 18: Japan APAC Engineering Plastic Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 19: South Korea APAC Engineering Plastic Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 20: South Korea APAC Engineering Plastic Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 21: ASEAN APAC Engineering Plastic Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 22: ASEAN APAC Engineering Plastic Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 23: Oceania APAC Engineering Plastic Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 24: Oceania APAC Engineering Plastic Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 25: Rest of Asia Pacific APAC Engineering Plastic Industry Revenue (undefined) Forecast, by Application 2020 & 2033

- Table 26: Rest of Asia Pacific APAC Engineering Plastic Industry Volume (K Tons) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the APAC Engineering Plastic Industry?

The projected CAGR is approximately 4.6%.

2. Which companies are prominent players in the APAC Engineering Plastic Industry?

Key companies in the market include Far Eastern New Century Corporation, Sumitomo Chemical Co Ltd, Asahi Kasei Corporation, Formosa Plastics Group, Solvay, Mitsubishi Chemical Corporation, Toray Industries Inc, CHIMEI, China Petroleum & Chemical Corporation, Lotte Chemical, LG Chem, Sinochem, Covestro AG, China Resources (Holdings) Co Ltd, Sanfame Group.

3. What are the main segments of the APAC Engineering Plastic Industry?

The market segments include End User Industry, Resin Type.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

Huge Growth in the Polyurethane Foam Application; Increasing Demand from the Construction Industry.

6. What are the notable trends driving market growth?

OTHER KEY INDUSTRY TRENDS COVERED IN THE REPORT.

7. Are there any restraints impacting market growth?

Shortage and Increased Price of Raw Material; Other Restraints.

8. Can you provide examples of recent developments in the market?

February 2023: Covestro AG introduced Makrolon 3638 polycarbonate for healthcare and life sciences applications such as drug delivery devices, wellness and wearable devices, and single-use containers for biopharmaceutical manufacturing.August 2022: Toray Industries Inc. introduced Toraypearl PA6, which claims to provide outstanding high strength, heat resistance, and surface smoothness for powder bed fusion 3D printers.August 2022: Covestro AG announced plans to build its first dedicated line for the mechanical recycling (MCR) of polycarbonates in Shanghai, China, to create more sustainable solutions, primarily for electrical and electronic, automotive, and consumer goods applications.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A and volume, measured in K Tons.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "APAC Engineering Plastic Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the APAC Engineering Plastic Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the APAC Engineering Plastic Industry?

To stay informed about further developments, trends, and reports in the APAC Engineering Plastic Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence