Key Insights

The global Tungsten Carbide market is experiencing robust growth, projected to reach $17.70 Billion by 2025, driven by a compound annual growth rate (CAGR) of 6.43% during the forecast period of 2025-2033. This expansion is significantly fueled by the increasing demand for high-performance materials across key industries. The aerospace and defense sector relies on tungsten carbide for its exceptional hardness, wear resistance, and high-temperature stability in critical components like turbine blades and drilling tools. Similarly, the automotive industry utilizes tungsten carbide in engine parts, wear-resistant coatings, and cutting tools for efficient manufacturing. The mining and construction industries are major consumers, employing tungsten carbide for drill bits, cutting tools, and wear parts essential for excavation and infrastructure development. Furthermore, the burgeoning electronics sector is finding new applications for tungsten carbide in semiconductor manufacturing and various precision components.

Tungsten Carbide Industry Market Size (In Billion)

The market's trajectory is also shaped by key trends such as advancements in sintering technologies and the development of novel composite materials incorporating tungsten carbide for enhanced properties. The growing emphasis on sustainability and efficiency in manufacturing processes further bolsters its adoption. However, certain factors could influence the market's pace. The volatility in raw material prices, particularly for tungsten ore, and the stringent environmental regulations associated with its processing present potential restraints. Despite these challenges, the inherent superior properties of tungsten carbide, including its extreme hardness and durability, ensure its continued indispensability across a wide spectrum of industrial applications. The Asia Pacific region, led by China, is anticipated to maintain its dominance due to substantial manufacturing capabilities and growing domestic demand.

Tungsten Carbide Industry Company Market Share

Comprehensive Analysis of the Global Tungsten Carbide Market: Trends, Opportunities, and Future Projections (2019-2033)

Unlock critical insights into the dynamic global tungsten carbide industry with this in-depth market research report. Covering the study period of 2019–2033, with a base year of 2025 and a forecast period from 2025–2033, this report provides an unparalleled understanding of market structure, key dynamics, dominant regions, product innovations, and future outlook. Essential for industry professionals, investors, and stakeholders seeking to navigate the complexities and capitalize on the growth potential of this vital material.

Tungsten Carbide Industry Market Structure & Innovation Trends

The tungsten carbide market exhibits a moderate to high concentration, with key players like China Tungsten, Sandvik AB, and Kennametal Inc. dominating global production and innovation. Innovation drivers are primarily centered around enhancing material properties for extreme conditions, such as improved wear resistance, higher hardness, and increased toughness, crucial for sectors like mining and aerospace. Regulatory frameworks, particularly concerning environmental impact and sustainable sourcing of tungsten, are increasingly influential. Product substitutes, while present in some niche applications (e.g., ceramics, advanced polymers), struggle to match tungsten carbide's unique combination of hardness and strength. End-user demographics are shifting, with a growing demand from the burgeoning electronics sector and a continued strong reliance from automotive and construction industries. Mergers and acquisitions (M&A) activity is a significant trend, facilitating market consolidation and expansion into new geographies and applications. For instance, the acquisition of AgriCarb SAS by CERATIZIT S.A. in September 2022 exemplifies strategic moves to broaden market reach and leverage specialized expertise. Deal values in significant M&A transactions are estimated to be in the hundreds of billions of USD.

Tungsten Carbide Industry Market Dynamics & Trends

The global tungsten carbide market is poised for substantial growth, driven by an insatiable demand for high-performance materials across a spectrum of industries. A key growth driver is the escalating need for durable and wear-resistant components in heavy industries such as mining and construction, where tools made from cemented carbide are indispensable for drilling, cutting, and excavation. The automotive sector continues to be a significant consumer, utilizing tungsten carbide for engine components, cutting tools, and wear parts, benefiting from its ability to withstand high temperatures and pressures. The aerospace and defense industries rely on tungsten carbide for its superior strength-to-weight ratio and resistance to extreme conditions, integral to aircraft manufacturing and defense equipment. Furthermore, the electronics industry is witnessing increased adoption of tungsten carbide for specialized applications, including semiconductor manufacturing and precision tooling.

Technological disruptions are playing a pivotal role in shaping market dynamics. Advancements in powder metallurgy and sintering techniques are enabling the production of more complex geometries and microstructures, leading to enhanced material properties and performance. The development of novel tungsten carbide composites and alloys, often incorporating other refractory metals or binders, is expanding the application landscape. For example, research into tungsten-based cathode coatings for lithium-ion batteries, as explored by ZSW and H.C. Starck Tungsten Powders in June 2022, signifies a crucial step towards improving battery safety and performance, aligning with the global push for electric vehicles. This innovation could unlock substantial new market penetration.

Consumer preferences are increasingly leaning towards materials that offer longevity, efficiency, and reduced maintenance costs, all attributes that tungsten carbide embodies. The growing emphasis on sustainability and circular economy principles is also influencing the market, with a rising demand for recycled tungsten carbide powders, as highlighted by CERATIZIT S.A.'s full ownership of Stadler Mettale in February 2022, a significant supplier of secondary raw materials. Competitive dynamics are characterized by intense innovation, strategic partnerships, and a focus on cost-effectiveness. Companies are investing heavily in R&D to develop next-generation tungsten carbide products that cater to evolving industry needs. The market penetration of tungsten carbide is expected to continue its upward trajectory, supported by its intrinsic material advantages and ongoing technological advancements, with a projected Compound Annual Growth Rate (CAGR) in the high single digits.

Dominant Regions & Segments in Tungsten Carbide Industry

The global tungsten carbide market is geographically diverse, with Asia Pacific emerging as the dominant region, largely propelled by the manufacturing prowess and burgeoning industrial sectors of China. China's significant tungsten reserves and its expansive manufacturing base contribute to its leading position in both production and consumption. Within Asia Pacific, countries like South Korea and Japan are also substantial contributors, particularly in advanced applications within the electronics and automotive segments. North America and Europe remain critical markets, characterized by a strong presence of end-users in aerospace, automotive, and specialized industrial applications, driven by robust technological innovation and stringent quality demands.

The Cemented Carbide segment commands the largest market share, driven by its widespread use in tooling, wear parts, and construction equipment. Key drivers for this segment include the robust demand from the mining and construction industries, where the durability and hardness of cemented carbide are paramount for efficient operations. Economic policies supporting infrastructure development and resource extraction in emerging economies further bolster this segment.

The Coatings segment is experiencing significant growth, fueled by the demand for enhanced surface properties in various applications. In the automotive sector, tungsten carbide coatings improve the wear resistance and lifespan of engine components. The electronics industry utilizes these coatings for precision components and semiconductor manufacturing equipment, where extreme precision and durability are essential.

The Alloys segment, while smaller in volume compared to cemented carbide, represents a high-value market, particularly for specialized applications. In aerospace and defense, advanced tungsten carbide alloys are critical for components requiring exceptional strength and heat resistance.

Analyzing end-user segments:

- Mining & Construction: This remains a cornerstone for tungsten carbide demand, with relentless need for drill bits, cutting tools, and wear parts for heavy machinery. Economic policies promoting infrastructure development and mining exploration directly impact this segment's growth.

- Automotive: The automotive industry is a major consumer, utilizing tungsten carbide for engine components, cutting tools in manufacturing, and wear parts. The increasing production of vehicles and the growing adoption of electric vehicles, which also require precision components, are key drivers.

- Aerospace & Defense: This segment demands high-performance materials for critical applications. The stringent requirements for durability, strength, and resistance to extreme environments in aircraft and defense systems make tungsten carbide an indispensable material.

- Electronics: A rapidly growing segment, this includes applications in semiconductor manufacturing, precision tooling for microelectronics, and specialized components. Technological advancements and the miniaturization trend in electronics are boosting demand.

- Others (Medical, Sports, etc.): This diverse segment encompasses applications like surgical instruments, high-performance sports equipment (e.g., golf club heads, darts), and various niche industrial tools, showcasing the versatility of tungsten carbide.

The dominance of these regions and segments is a testament to the inherent properties of tungsten carbide and its indispensable role in modern industrial and technological advancements.

Tungsten Carbide Industry Product Innovations

Product innovations in the tungsten carbide industry are primarily focused on enhancing material performance for demanding applications and expanding its utility into novel sectors. Companies are developing advanced tungsten carbide composites and alloys with superior hardness, wear resistance, and toughness, often through refined powder metallurgy techniques and the incorporation of specialized binders or reinforcements. This includes the creation of sub-micron and nano-grained tungsten carbides for ultra-fine finishing and precision tooling. Furthermore, ongoing research into tungsten carbide coatings is yielding improved adhesion, thickness control, and tailored surface properties for specific environments, such as protective coatings for medical implants or high-performance cutting tools. The competitive advantage of these innovations lies in enabling longer tool life, higher machining speeds, and improved efficiency for end-users, while also opening doors to new applications in fields like additive manufacturing and energy storage.

Report Scope & Segmentation Analysis

This report offers a comprehensive analysis of the global tungsten carbide market, segmented by Application, End-User, and Region. The Application segments include Cemented carbide, representing the largest share due to its extensive use in cutting tools and wear parts; Coatings, offering enhanced surface properties and corrosion resistance; and Alloys, catering to high-performance applications.

The End-User segments analyzed are Aerospace & Defense, demanding materials with exceptional strength and durability; Automotive, a major consumer for engine components and tooling; Mining & Construction, relying on tungsten carbide for heavy-duty equipment; Electronics, utilizing it for precision manufacturing and components; and Others, encompassing diverse sectors like Medical and Sports. Each segment's growth projections, market sizes, and competitive dynamics are thoroughly examined, providing detailed insights into their specific contribution to the overall market.

Key Drivers of Tungsten Carbide Industry Growth

The tungsten carbide industry's growth is propelled by several interconnected factors. Technologically, continuous advancements in powder metallurgy and sintering processes are enabling the creation of materials with superior properties like enhanced hardness, wear resistance, and toughness, catering to increasingly stringent application requirements. Economically, the robust demand from key end-user industries such as mining and construction, driven by global infrastructure development and resource extraction, provides a foundational growth engine. The automotive sector's expansion and the ongoing transition to electric vehicles, which require precision-engineered components, also contribute significantly. Regulatory factors, while sometimes presenting challenges, can also drive innovation, particularly concerning environmental sustainability and the development of more efficient and longer-lasting products. The inherent material advantages of tungsten carbide, including its extreme hardness and high melting point, ensure its continued indispensability across critical industrial applications.

Challenges in the Tungsten Carbide Industry Sector

Despite its robust growth, the tungsten carbide industry faces several challenges. Regulatory hurdles, particularly concerning environmental regulations related to mining, processing, and waste disposal of tungsten, can increase operational costs and compliance burdens. Supply chain disruptions, often linked to geopolitical factors affecting tungsten ore availability and pricing, pose a significant risk, impacting production schedules and cost-effectiveness. Competitive pressures from alternative materials, although generally unable to match tungsten carbide's specific properties, can emerge in niche applications, requiring continuous innovation and value proposition reinforcement. Furthermore, the energy-intensive nature of tungsten carbide production contributes to operational costs and environmental concerns, necessitating investment in more sustainable manufacturing practices. The availability and fluctuating prices of raw tungsten ore are also a persistent challenge for manufacturers.

Emerging Opportunities in Tungsten Carbide Industry

Emerging opportunities in the tungsten carbide industry are diverse and promising. The burgeoning demand for high-performance materials in the rapidly expanding electronics sector, particularly for semiconductor manufacturing and precision tooling, presents a significant avenue for growth. The global shift towards electric vehicles (EVs) is creating new opportunities for specialized tungsten carbide components and coatings in battery manufacturing and other EV-related technologies. Advancements in additive manufacturing (3D printing) are enabling the creation of complex tungsten carbide parts with enhanced functionalities, opening up new application frontiers. Furthermore, the increasing focus on sustainability and circular economy principles is driving demand for recycled tungsten carbide powders, offering a sustainable and cost-effective alternative for manufacturers. Exploration into novel applications in renewable energy sectors, such as components for advanced energy storage systems, also holds considerable potential.

Leading Players in the Tungsten Carbide Industry Market

- Umicore

- Federal Carbide Company

- American Elements

- Guangdong Xianglu Tungsten Co Ltd

- H C Starck Tungsten GmbH

- Sandvik AB

- Kennametal Inc

- CERATIZIT S A

- Jiangxi Yaosheng Tungsten Co Ltd

- China Tungsten

- Extramet Products LLC

- CY Carbide Mfg Co Ltd

- Buffalo Tungsten Inc

- Sumitomo Electric Industries Ltd

Key Developments in Tungsten Carbide Industry Industry

- September 2022: CERATIZIT S.A. announced the acquisition of all the shares of AgriCarb SAS, a global leader in tungsten carbide agricultural wear parts for over 35 years. This acquisition will help the company enter new markets with the help of a high degree of added value and expertise in the field of hybrid tools made of steel and tungsten carbide.

- June 2022: The Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and H.C. Starck Tungsten Powders, a subsidiary of the Masan High-Tech Materials Group, are working together to investigate the application of tungsten-based cathode coatings in lithium-ion batteries. This partnership is considered a crucial milestone in the growth of elements like tungsten in the development and use of batteries, making batteries safer and enhancing their performance, a vital component of wider adoption and application in the worldwide EV push.

- February 2022: CERATIZIT S.A. announced the takeover of the remaining 50% of the shares of Stadler Mettale and thus became the sole owner of the company. The company is one of the most important sources of secondary raw materials for making tungsten and tungsten carbide powders, and CERATIZIT S.A. depends on the company a lot.

Future Outlook for Tungsten Carbide Industry Market

The future outlook for the tungsten carbide industry is exceptionally positive, characterized by sustained growth and evolving market dynamics. The increasing industrialization in emerging economies, coupled with ongoing technological advancements, will continue to fuel demand across key application segments. The push towards electrification in the automotive sector will create new avenues for specialized tungsten carbide products, while the aerospace industry's continuous need for high-performance materials ensures a stable demand base. Opportunities in sectors like renewable energy and advanced manufacturing will further diversify the market. Strategic investments in R&D, focusing on material optimization, sustainability, and novel applications, will be crucial for companies to maintain a competitive edge. The industry is also likely to witness continued consolidation through strategic M&A activities, leading to a more streamlined and innovation-driven landscape. The global tungsten carbide market is set to expand significantly, driven by its inherent material superiority and its critical role in enabling technological progress across diverse industries.

Tungsten Carbide Industry Segmentation

-

1. Application

- 1.1. Cemented carbide

- 1.2. Coatings

- 1.3. Alloys

-

2. End-user

- 2.1. Aerospace & Defense

- 2.2. Automotive

- 2.3. Mining & Construction

- 2.4. Electronics

- 2.5. Others (Medical, Sports, etc.)

Tungsten Carbide Industry Segmentation By Geography

-

1. Asia Pacific

- 1.1. China

- 1.2. India

- 1.3. Japan

- 1.4. South Korea

- 1.5. Rest of Asia Pacific

-

2. North America

- 2.1. United States

- 2.2. Canada

- 2.3. Mexico

-

3. Europe

- 3.1. Germany

- 3.2. United Kingdom

- 3.3. Italy

- 3.4. France

- 3.5. Rest of Europe

-

4. Rest of the World

- 4.1. South America

- 4.2. Middle East

Tungsten Carbide Industry Regional Market Share

Geographic Coverage of Tungsten Carbide Industry

Tungsten Carbide Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 6.43% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasing Applications of Tungsten Carbide in Various End-user Industries; Recylable Property of Tungsten carbide

- 3.3. Market Restrains

- 3.3.1. Toxicity of Tungsten carbide; Other Restraints

- 3.4. Market Trends

- 3.4.1. Cement Carbide to Drive the Market Growth

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Tungsten Carbide Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Cemented carbide

- 5.1.2. Coatings

- 5.1.3. Alloys

- 5.2. Market Analysis, Insights and Forecast - by End-user

- 5.2.1. Aerospace & Defense

- 5.2.2. Automotive

- 5.2.3. Mining & Construction

- 5.2.4. Electronics

- 5.2.5. Others (Medical, Sports, etc.)

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Asia Pacific

- 5.3.2. North America

- 5.3.3. Europe

- 5.3.4. Rest of the World

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. Asia Pacific Tungsten Carbide Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Cemented carbide

- 6.1.2. Coatings

- 6.1.3. Alloys

- 6.2. Market Analysis, Insights and Forecast - by End-user

- 6.2.1. Aerospace & Defense

- 6.2.2. Automotive

- 6.2.3. Mining & Construction

- 6.2.4. Electronics

- 6.2.5. Others (Medical, Sports, etc.)

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. North America Tungsten Carbide Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Cemented carbide

- 7.1.2. Coatings

- 7.1.3. Alloys

- 7.2. Market Analysis, Insights and Forecast - by End-user

- 7.2.1. Aerospace & Defense

- 7.2.2. Automotive

- 7.2.3. Mining & Construction

- 7.2.4. Electronics

- 7.2.5. Others (Medical, Sports, etc.)

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Tungsten Carbide Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Cemented carbide

- 8.1.2. Coatings

- 8.1.3. Alloys

- 8.2. Market Analysis, Insights and Forecast - by End-user

- 8.2.1. Aerospace & Defense

- 8.2.2. Automotive

- 8.2.3. Mining & Construction

- 8.2.4. Electronics

- 8.2.5. Others (Medical, Sports, etc.)

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Rest of the World Tungsten Carbide Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Cemented carbide

- 9.1.2. Coatings

- 9.1.3. Alloys

- 9.2. Market Analysis, Insights and Forecast - by End-user

- 9.2.1. Aerospace & Defense

- 9.2.2. Automotive

- 9.2.3. Mining & Construction

- 9.2.4. Electronics

- 9.2.5. Others (Medical, Sports, etc.)

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Competitive Analysis

- 10.1. Global Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 Umicore

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 Federal Carbide Company

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 American Elements

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 Guangdong Xianglu Tungsten Co Ltd

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 H C Starck Tungsten GmbH

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Sandvik AB

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 Kennametal Inc

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 CERATIZIT S A

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 Jiangxi Yaosheng Tungsten Co Ltd

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 China Tungsten

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.11 Extramet Products LLC

- 10.2.11.1. Overview

- 10.2.11.2. Products

- 10.2.11.3. SWOT Analysis

- 10.2.11.4. Recent Developments

- 10.2.11.5. Financials (Based on Availability)

- 10.2.12 CY Carbide Mfg Co Ltd

- 10.2.12.1. Overview

- 10.2.12.2. Products

- 10.2.12.3. SWOT Analysis

- 10.2.12.4. Recent Developments

- 10.2.12.5. Financials (Based on Availability)

- 10.2.13 Buffalo Tungsten Inc

- 10.2.13.1. Overview

- 10.2.13.2. Products

- 10.2.13.3. SWOT Analysis

- 10.2.13.4. Recent Developments

- 10.2.13.5. Financials (Based on Availability)

- 10.2.14 Sumitomo Electric Industries Ltd

- 10.2.14.1. Overview

- 10.2.14.2. Products

- 10.2.14.3. SWOT Analysis

- 10.2.14.4. Recent Developments

- 10.2.14.5. Financials (Based on Availability)

- 10.2.1 Umicore

List of Figures

- Figure 1: Global Tungsten Carbide Industry Revenue Breakdown (Billion, %) by Region 2025 & 2033

- Figure 2: Global Tungsten Carbide Industry Volume Breakdown (K Tons, %) by Region 2025 & 2033

- Figure 3: Asia Pacific Tungsten Carbide Industry Revenue (Billion), by Application 2025 & 2033

- Figure 4: Asia Pacific Tungsten Carbide Industry Volume (K Tons), by Application 2025 & 2033

- Figure 5: Asia Pacific Tungsten Carbide Industry Revenue Share (%), by Application 2025 & 2033

- Figure 6: Asia Pacific Tungsten Carbide Industry Volume Share (%), by Application 2025 & 2033

- Figure 7: Asia Pacific Tungsten Carbide Industry Revenue (Billion), by End-user 2025 & 2033

- Figure 8: Asia Pacific Tungsten Carbide Industry Volume (K Tons), by End-user 2025 & 2033

- Figure 9: Asia Pacific Tungsten Carbide Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 10: Asia Pacific Tungsten Carbide Industry Volume Share (%), by End-user 2025 & 2033

- Figure 11: Asia Pacific Tungsten Carbide Industry Revenue (Billion), by Country 2025 & 2033

- Figure 12: Asia Pacific Tungsten Carbide Industry Volume (K Tons), by Country 2025 & 2033

- Figure 13: Asia Pacific Tungsten Carbide Industry Revenue Share (%), by Country 2025 & 2033

- Figure 14: Asia Pacific Tungsten Carbide Industry Volume Share (%), by Country 2025 & 2033

- Figure 15: North America Tungsten Carbide Industry Revenue (Billion), by Application 2025 & 2033

- Figure 16: North America Tungsten Carbide Industry Volume (K Tons), by Application 2025 & 2033

- Figure 17: North America Tungsten Carbide Industry Revenue Share (%), by Application 2025 & 2033

- Figure 18: North America Tungsten Carbide Industry Volume Share (%), by Application 2025 & 2033

- Figure 19: North America Tungsten Carbide Industry Revenue (Billion), by End-user 2025 & 2033

- Figure 20: North America Tungsten Carbide Industry Volume (K Tons), by End-user 2025 & 2033

- Figure 21: North America Tungsten Carbide Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 22: North America Tungsten Carbide Industry Volume Share (%), by End-user 2025 & 2033

- Figure 23: North America Tungsten Carbide Industry Revenue (Billion), by Country 2025 & 2033

- Figure 24: North America Tungsten Carbide Industry Volume (K Tons), by Country 2025 & 2033

- Figure 25: North America Tungsten Carbide Industry Revenue Share (%), by Country 2025 & 2033

- Figure 26: North America Tungsten Carbide Industry Volume Share (%), by Country 2025 & 2033

- Figure 27: Europe Tungsten Carbide Industry Revenue (Billion), by Application 2025 & 2033

- Figure 28: Europe Tungsten Carbide Industry Volume (K Tons), by Application 2025 & 2033

- Figure 29: Europe Tungsten Carbide Industry Revenue Share (%), by Application 2025 & 2033

- Figure 30: Europe Tungsten Carbide Industry Volume Share (%), by Application 2025 & 2033

- Figure 31: Europe Tungsten Carbide Industry Revenue (Billion), by End-user 2025 & 2033

- Figure 32: Europe Tungsten Carbide Industry Volume (K Tons), by End-user 2025 & 2033

- Figure 33: Europe Tungsten Carbide Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 34: Europe Tungsten Carbide Industry Volume Share (%), by End-user 2025 & 2033

- Figure 35: Europe Tungsten Carbide Industry Revenue (Billion), by Country 2025 & 2033

- Figure 36: Europe Tungsten Carbide Industry Volume (K Tons), by Country 2025 & 2033

- Figure 37: Europe Tungsten Carbide Industry Revenue Share (%), by Country 2025 & 2033

- Figure 38: Europe Tungsten Carbide Industry Volume Share (%), by Country 2025 & 2033

- Figure 39: Rest of the World Tungsten Carbide Industry Revenue (Billion), by Application 2025 & 2033

- Figure 40: Rest of the World Tungsten Carbide Industry Volume (K Tons), by Application 2025 & 2033

- Figure 41: Rest of the World Tungsten Carbide Industry Revenue Share (%), by Application 2025 & 2033

- Figure 42: Rest of the World Tungsten Carbide Industry Volume Share (%), by Application 2025 & 2033

- Figure 43: Rest of the World Tungsten Carbide Industry Revenue (Billion), by End-user 2025 & 2033

- Figure 44: Rest of the World Tungsten Carbide Industry Volume (K Tons), by End-user 2025 & 2033

- Figure 45: Rest of the World Tungsten Carbide Industry Revenue Share (%), by End-user 2025 & 2033

- Figure 46: Rest of the World Tungsten Carbide Industry Volume Share (%), by End-user 2025 & 2033

- Figure 47: Rest of the World Tungsten Carbide Industry Revenue (Billion), by Country 2025 & 2033

- Figure 48: Rest of the World Tungsten Carbide Industry Volume (K Tons), by Country 2025 & 2033

- Figure 49: Rest of the World Tungsten Carbide Industry Revenue Share (%), by Country 2025 & 2033

- Figure 50: Rest of the World Tungsten Carbide Industry Volume Share (%), by Country 2025 & 2033

List of Tables

- Table 1: Global Tungsten Carbide Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 2: Global Tungsten Carbide Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 3: Global Tungsten Carbide Industry Revenue Billion Forecast, by End-user 2020 & 2033

- Table 4: Global Tungsten Carbide Industry Volume K Tons Forecast, by End-user 2020 & 2033

- Table 5: Global Tungsten Carbide Industry Revenue Billion Forecast, by Region 2020 & 2033

- Table 6: Global Tungsten Carbide Industry Volume K Tons Forecast, by Region 2020 & 2033

- Table 7: Global Tungsten Carbide Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 8: Global Tungsten Carbide Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 9: Global Tungsten Carbide Industry Revenue Billion Forecast, by End-user 2020 & 2033

- Table 10: Global Tungsten Carbide Industry Volume K Tons Forecast, by End-user 2020 & 2033

- Table 11: Global Tungsten Carbide Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 12: Global Tungsten Carbide Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 13: China Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 14: China Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 15: India Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 16: India Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 17: Japan Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 18: Japan Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 19: South Korea Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 20: South Korea Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 21: Rest of Asia Pacific Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 22: Rest of Asia Pacific Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 23: Global Tungsten Carbide Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 24: Global Tungsten Carbide Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 25: Global Tungsten Carbide Industry Revenue Billion Forecast, by End-user 2020 & 2033

- Table 26: Global Tungsten Carbide Industry Volume K Tons Forecast, by End-user 2020 & 2033

- Table 27: Global Tungsten Carbide Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 28: Global Tungsten Carbide Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 29: United States Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 30: United States Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 31: Canada Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 32: Canada Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 33: Mexico Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 34: Mexico Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 35: Global Tungsten Carbide Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 36: Global Tungsten Carbide Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 37: Global Tungsten Carbide Industry Revenue Billion Forecast, by End-user 2020 & 2033

- Table 38: Global Tungsten Carbide Industry Volume K Tons Forecast, by End-user 2020 & 2033

- Table 39: Global Tungsten Carbide Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 40: Global Tungsten Carbide Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 41: Germany Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 42: Germany Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 43: United Kingdom Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 44: United Kingdom Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 45: Italy Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 46: Italy Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 47: France Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 48: France Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 49: Rest of Europe Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 50: Rest of Europe Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 51: Global Tungsten Carbide Industry Revenue Billion Forecast, by Application 2020 & 2033

- Table 52: Global Tungsten Carbide Industry Volume K Tons Forecast, by Application 2020 & 2033

- Table 53: Global Tungsten Carbide Industry Revenue Billion Forecast, by End-user 2020 & 2033

- Table 54: Global Tungsten Carbide Industry Volume K Tons Forecast, by End-user 2020 & 2033

- Table 55: Global Tungsten Carbide Industry Revenue Billion Forecast, by Country 2020 & 2033

- Table 56: Global Tungsten Carbide Industry Volume K Tons Forecast, by Country 2020 & 2033

- Table 57: South America Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 58: South America Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

- Table 59: Middle East Tungsten Carbide Industry Revenue (Billion) Forecast, by Application 2020 & 2033

- Table 60: Middle East Tungsten Carbide Industry Volume (K Tons) Forecast, by Application 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Tungsten Carbide Industry?

The projected CAGR is approximately 6.43%.

2. Which companies are prominent players in the Tungsten Carbide Industry?

Key companies in the market include Umicore, Federal Carbide Company, American Elements, Guangdong Xianglu Tungsten Co Ltd, H C Starck Tungsten GmbH, Sandvik AB, Kennametal Inc, CERATIZIT S A, Jiangxi Yaosheng Tungsten Co Ltd, China Tungsten, Extramet Products LLC, CY Carbide Mfg Co Ltd, Buffalo Tungsten Inc, Sumitomo Electric Industries Ltd.

3. What are the main segments of the Tungsten Carbide Industry?

The market segments include Application, End-user.

4. Can you provide details about the market size?

The market size is estimated to be USD 17.70 Billion as of 2022.

5. What are some drivers contributing to market growth?

Increasing Applications of Tungsten Carbide in Various End-user Industries; Recylable Property of Tungsten carbide.

6. What are the notable trends driving market growth?

Cement Carbide to Drive the Market Growth.

7. Are there any restraints impacting market growth?

Toxicity of Tungsten carbide; Other Restraints.

8. Can you provide examples of recent developments in the market?

September 2022: CERATIZIT S.A. announced the acquisition of all the shares of AgriCarb SAS, a global leader in tungsten carbide agricultural wear parts for over 35 years. This acquisition will help the company enter new markets. with the help of a high degree of added value and expertise in the field of hybrid tools made of steel and tungsten carbide.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Billion and volume, measured in K Tons.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Tungsten Carbide Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Tungsten Carbide Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Tungsten Carbide Industry?

To stay informed about further developments, trends, and reports in the Tungsten Carbide Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

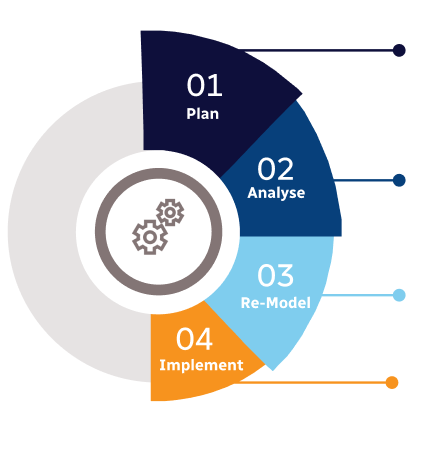

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence