Key Insights

The Australian automotive parts magnesium die casting market, projected to reach $7.26 billion by 2025, is set for robust expansion. Experts forecast a Compound Annual Growth Rate (CAGR) of 15.35% from 2025 to 2033. This significant growth is propelled by the automotive industry's increasing focus on lightweight vehicle construction to enhance fuel efficiency and reduce emissions. The accelerating adoption of electric vehicles (EVs) further amplifies this demand, as magnesium's inherent lightweight nature and superior casting capabilities are crucial for EV battery enclosures and other critical components. Advancements in die casting technologies, including semi-solid die casting, are also contributing to improved part quality and decreased production costs, thereby supporting market expansion. Nevertheless, the market confronts obstacles such as the comparatively higher cost of magnesium versus alternative materials like aluminum, and volatility in raw magnesium pricing, which can affect profitability. Analysis of market segmentation reveals substantial demand across diverse applications, including body assemblies, engine components, and transmission parts, with pressure die casting dominating the manufacturing process. The competitive landscape features a mix of domestic and international enterprises, presenting opportunities for both established entities and nascent businesses.

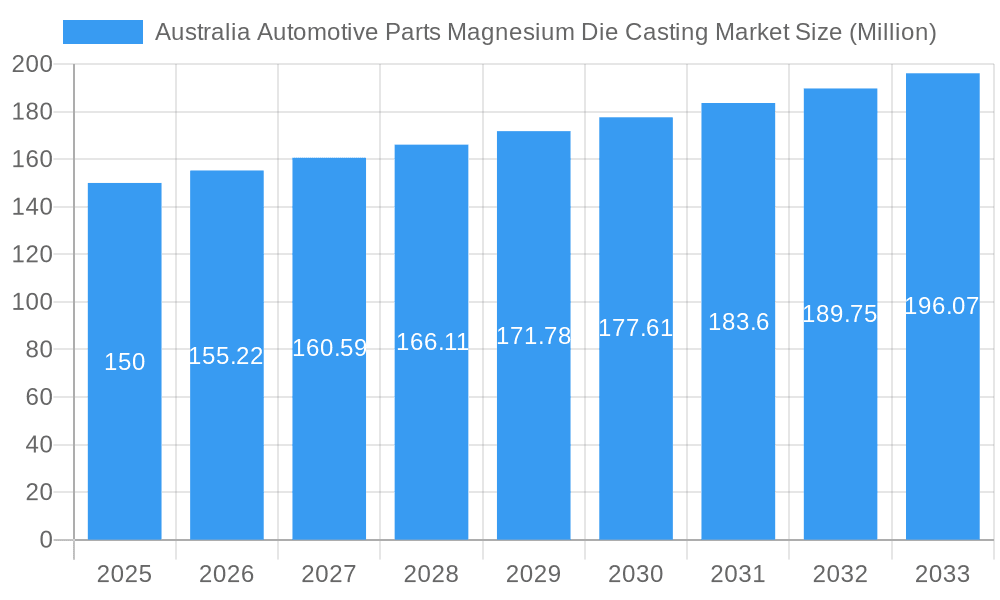

Australia Automotive Parts Magnesium Die Casting Market Market Size (In Billion)

Future projections for the Australian automotive parts magnesium die casting market indicate sustained growth through the 2025-2033 forecast period. This expansion will be primarily driven by government incentives supporting sustainable transportation and continuous innovation within the automotive sector. While raw material cost and competition from substitute materials present challenges, the inherent advantages of magnesium's lightweight and high-strength properties are anticipated to mitigate these concerns. Market participants are expected to prioritize research and development to refine casting methodologies and identify novel applications for magnesium die castings in automotive manufacturing. Strategic alliances and collaborations will likely be instrumental in addressing supply chain complexities and developing more economical production solutions. The distinct focus on the Australian market offers valuable insights into a sector responding to specific domestic automotive manufacturing and regulatory trends.

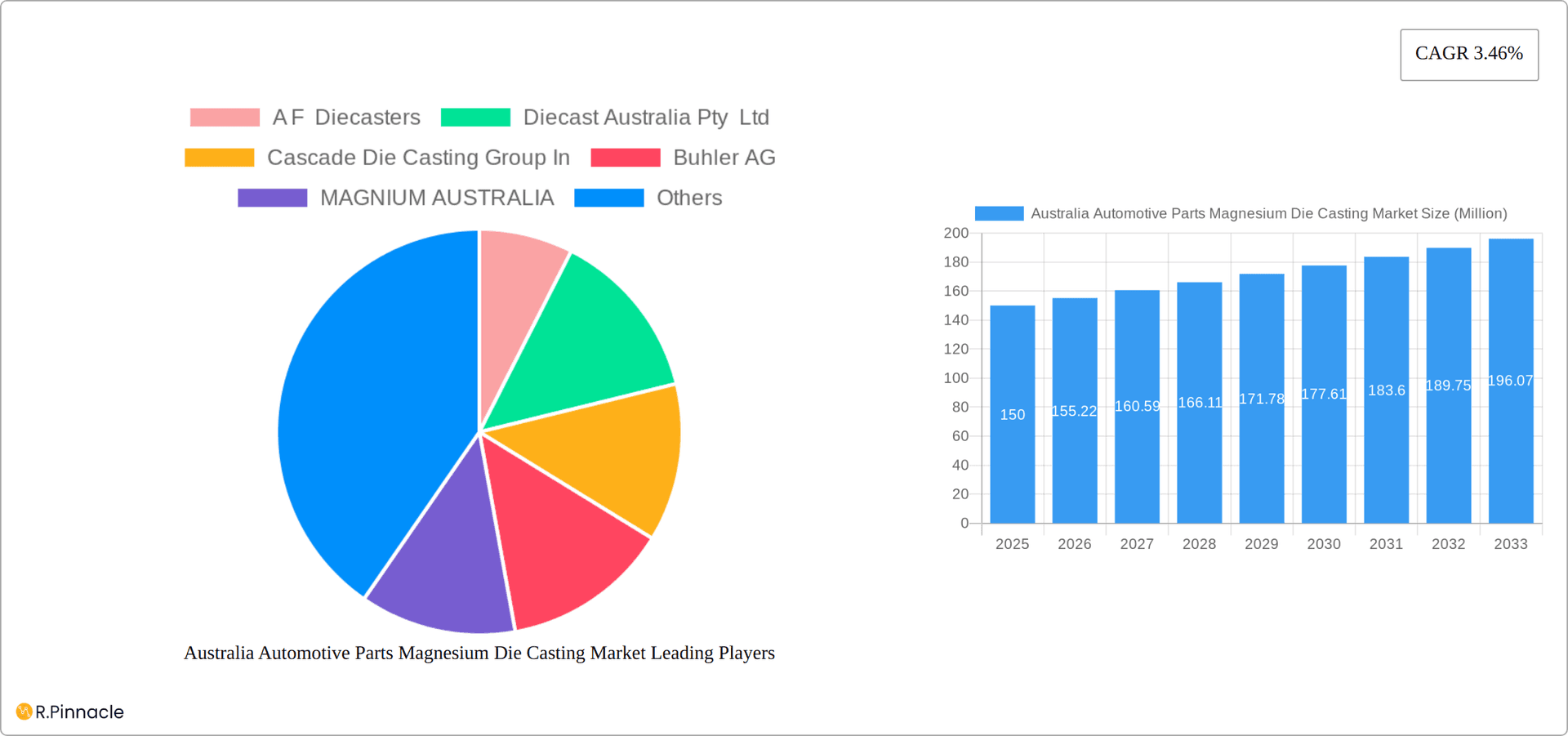

Australia Automotive Parts Magnesium Die Casting Market Company Market Share

Australia Automotive Parts Magnesium Die Casting Market Report: 2019-2033

This comprehensive report provides an in-depth analysis of the Australia Automotive Parts Magnesium Die Casting Market, offering valuable insights for industry professionals, investors, and stakeholders. The report covers the period 2019-2033, with a base year of 2025 and a forecast period of 2025-2033. The market is segmented by application type (Body Assemblies, Engine Parts, Transmission Parts, Other Application Types) and production process type (Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, Semi-Solid Die Casting). Key players analyzed include A F Diecasters, Diecast Australia Pty Ltd, Cascade Die Casting Group, Buhler AG, MAGNIUM AUSTRALIA, Dongguan Minghe Die Casting Company, HARROP ENGINEERING, and Kemlows Diecasting Products Ltd. The market is expected to reach xx Million by 2033, exhibiting a CAGR of xx%.

Australia Automotive Parts Magnesium Die Casting Market Market Structure & Innovation Trends

This section analyzes the competitive landscape, including market concentration, key players' market share, and M&A activities. The report examines the influence of innovation drivers, such as advancements in die casting technology and lightweighting trends in the automotive industry. Regulatory frameworks impacting the market and the role of product substitutes are also discussed. End-user demographics and their impact on market demand are assessed, providing a detailed overview of the market structure.

- Market Concentration: The Australian automotive parts magnesium die casting market exhibits a moderately concentrated structure, with a few dominant players holding significant market share. The precise market share distribution among key players like A F Diecasters, Diecast Australia Pty Ltd, and Cascade Die Casting Group is analyzed within the full report, revealing the level of competition. The xx Million market is estimated to be shared among these and other companies.

- Innovation Drivers: Lightweighting regulations and the increasing demand for fuel-efficient vehicles are major drivers of innovation. Advancements in die casting technologies, particularly semi-solid die casting, are enhancing the quality and efficiency of production.

- M&A Activity: The report details recent mergers and acquisitions within the sector, including deal values and their impact on the market structure. For example, the May 2022 agreement between GF Casting Solutions and the Bocar Group highlights strategic partnerships and market consolidation.

- Regulatory Frameworks: Government policies promoting sustainable manufacturing and the adoption of lightweight materials influence market growth and investment decisions.

Australia Automotive Parts Magnesium Die Casting Market Market Dynamics & Trends

The Australian automotive parts magnesium die casting market is characterized by a dynamic interplay of technological advancements, evolving consumer demands, and a robust competitive landscape. This section provides an in-depth analysis of the forces shaping market growth, including a detailed examination of both the drivers propelling its expansion and the restraints that may pose challenges. We will also explore actionable insights into future market trends, the intricate competitive environment, and the transformative impact of emerging technologies on the sector.

- Market Growth Drivers: A significant surge in the demand for lightweight vehicles, driven by the global imperative for enhanced fuel efficiency and reduced emissions, is a primary catalyst for market expansion. Furthermore, supportive government initiatives aimed at promoting the adoption of advanced materials like magnesium alloys, coupled with the sustained growth and evolution of the automotive manufacturing and repair industries within Australia, are profoundly influencing market dynamics.

- Technological Disruptions: Continuous innovation in die casting technologies is revolutionizing production methodologies. Advancements such as high-pressure die casting and cutting-edge semi-solid die casting techniques are not only boosting production efficiency but also significantly elevating product quality and component performance. The integration of automation and the principles of Industry 4.0 are poised to further transform the manufacturing processes, leading to more sophisticated and cost-effective production of magnesium automotive parts.

- Consumer Preferences: The modern automotive consumer places a high premium on fuel-efficient and environmentally conscious vehicles. This growing preference directly translates into an increased demand for lightweight materials, with magnesium alloys emerging as a preferred choice for various automotive components due to their exceptional strength-to-weight ratio.

- Competitive Dynamics: The competitive arena is vibrant, with key players actively engaged in strategic maneuvers to secure market share. Our analysis delves into the diverse competitive strategies employed, including meticulous product differentiation efforts, agile pricing strategies tailored to market segments, and proactive market penetration tactics aimed at capturing emerging opportunities.

Dominant Regions & Segments in Australia Automotive Parts Magnesium Die Casting Market

This section identifies the leading regions and segments within the Australian automotive parts magnesium die casting market. The analysis considers both application types and production process types, highlighting the factors driving their dominance.

- Dominant Application Type: The report details which application type (Body Assemblies, Engine Parts, Transmission Parts, or Other Application Types) holds the largest market share and the reasons behind its dominance. This includes factors such as vehicle production trends and design preferences.

- Dominant Production Process Type: The analysis identifies whether Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, or Semi-Solid Die Casting is the dominant production method and explains the underlying factors.

- Key Drivers: Bullet points will detail specific economic policies, infrastructure development, and other regional factors contributing to the dominance of particular regions or segments. For example, the presence of automotive manufacturing hubs would strongly influence regional market shares.

Australia Automotive Parts Magnesium Die Casting Market Product Innovations

This section meticulously details recent and pioneering product developments within the Australia automotive parts magnesium die casting market, emphasizing their specific applications and the distinct competitive advantages they offer. We highlight the crucial role of technological advancements and precise market fit in driving these innovations, providing a concise yet comprehensive snapshot of current groundbreaking developments and their anticipated impact on the industry. The focus remains steadfast on improvements in material science, sophisticated casting processes, and innovative designs, all aimed at the production of components that are not only lighter and stronger but also significantly more efficient and sustainable.

Report Scope & Segmentation Analysis

This section outlines the scope of the report and details the market segmentation by application type and production process type. It provides growth projections, market sizes, and competitive dynamics for each segment.

- Application Type Segmentation: This paragraph details market size and growth projections for Body Assemblies, Engine Parts, Transmission Parts, and Other Application Types segments, along with a competitive analysis of each.

- Production Process Type Segmentation: This paragraph details market size and growth projections for Pressure Die Casting, Vacuum Die Casting, Squeeze Die Casting, and Semi-Solid Die Casting segments, along with a competitive analysis of each.

Key Drivers of Australia Automotive Parts Magnesium Die Casting Market Growth

This section identifies and elaborates on the pivotal factors propelling the growth of the Australia automotive parts magnesium die casting market. We examine the synergistic influence of technological advancements, robust economic factors, and the presence of supportive government regulations. Specific, illustrative examples will be provided to concretely demonstrate how these drivers are shaping the market's trajectory.

Challenges in the Australia Automotive Parts Magnesium Die Casting Market Sector

This section discusses the challenges faced by the market, including regulatory hurdles, supply chain issues, and competitive pressures. Quantifiable impacts of these challenges on market growth are highlighted.

Emerging Opportunities in Australia Automotive Parts Magnesium Die Casting Market

This section highlights emerging trends and opportunities in the market, such as new market segments, technological advancements, and evolving consumer preferences.

Leading Players in the Australia Automotive Parts Magnesium Die Casting Market Market

- A F Diecasters

- Diecast Australia Pty Ltd

- Cascade Die Casting Group

- Buhler AG

- MAGNIUM AUSTRALIA

- Dongguan Minghe Die Casting Company

- HARROP ENGINEERING

- Kemlows Diecasting Products Ltd

Key Developments in Australia Automotive Parts Magnesium Die Casting Market Industry

- July 2022: Magnium Australia developed manufacturing technology enabling Australia to capitalize on a USD 300 billion magnesium export opportunity. This significantly enhanced the market’s potential and competitiveness on a global scale.

- May 2022: GF Casting Solutions and the Bocar Group signed an agreement to offer a specialized range of products and services worldwide. This strategic partnership could lead to increased market competition and innovation.

Future Outlook for Australia Automotive Parts Magnesium Die Casting Market Market

This section offers a comprehensive outlook on the growth trajectory and future potential of the Australia automotive parts magnesium die casting market, with a specific focus on projected market size and the identification of strategic opportunities. The persistent and accelerating trend towards vehicle lightweighting within the global automotive industry, synergistically amplified by ongoing technological advancements in magnesium die casting processes, is expected to be a significant driver of substantial market expansion in the foreseeable future. The report concludes by delineating promising strategic pathways and initiatives that companies can adopt to effectively capitalize on this burgeoning market.

Australia Automotive Parts Magnesium Die Casting Market Segmentation

-

1. Production Process Type

- 1.1. Pressure Die Casting

- 1.2. Vacuum Die Casting

- 1.3. Squeeze Die Casting

- 1.4. Semi-Solid Die Casting

-

2. Application Type

- 2.1. Body Assemblies

- 2.2. Engine Parts

- 2.3. Transmission Parts

- 2.4. Other Aplication Types

Australia Automotive Parts Magnesium Die Casting Market Segmentation By Geography

- 1. Australia

Australia Automotive Parts Magnesium Die Casting Market Regional Market Share

Geographic Coverage of Australia Automotive Parts Magnesium Die Casting Market

Australia Automotive Parts Magnesium Die Casting Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 15.35% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Automotive Industry Continues to Witness Steady Growth in Vehicle Production; Growing Awareness of Air Pollution and Health Concerns

- 3.3. Market Restrains

- 3.3.1. Shift towards Disposable Filters

- 3.4. Market Trends

- 3.4.1. Pressure Die Casting Process dominating the market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Australia Automotive Parts Magnesium Die Casting Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 5.1.1. Pressure Die Casting

- 5.1.2. Vacuum Die Casting

- 5.1.3. Squeeze Die Casting

- 5.1.4. Semi-Solid Die Casting

- 5.2. Market Analysis, Insights and Forecast - by Application Type

- 5.2.1. Body Assemblies

- 5.2.2. Engine Parts

- 5.2.3. Transmission Parts

- 5.2.4. Other Aplication Types

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. Australia

- 5.1. Market Analysis, Insights and Forecast - by Production Process Type

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 A F Diecasters

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Diecast Australia Pty Ltd

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Cascade Die Casting Group In

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Buhler AG

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 MAGNIUM AUSTRALIA

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Dongguan Minghe Die Casting Company

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 HARROP ENGINEERING

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Kemlows Diecasting Products Ltd

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.1 A F Diecasters

List of Figures

- Figure 1: Australia Automotive Parts Magnesium Die Casting Market Revenue Breakdown (billion, %) by Product 2025 & 2033

- Figure 2: Australia Automotive Parts Magnesium Die Casting Market Share (%) by Company 2025

List of Tables

- Table 1: Australia Automotive Parts Magnesium Die Casting Market Revenue billion Forecast, by Production Process Type 2020 & 2033

- Table 2: Australia Automotive Parts Magnesium Die Casting Market Revenue billion Forecast, by Application Type 2020 & 2033

- Table 3: Australia Automotive Parts Magnesium Die Casting Market Revenue billion Forecast, by Region 2020 & 2033

- Table 4: Australia Automotive Parts Magnesium Die Casting Market Revenue billion Forecast, by Production Process Type 2020 & 2033

- Table 5: Australia Automotive Parts Magnesium Die Casting Market Revenue billion Forecast, by Application Type 2020 & 2033

- Table 6: Australia Automotive Parts Magnesium Die Casting Market Revenue billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Australia Automotive Parts Magnesium Die Casting Market?

The projected CAGR is approximately 15.35%.

2. Which companies are prominent players in the Australia Automotive Parts Magnesium Die Casting Market?

Key companies in the market include A F Diecasters, Diecast Australia Pty Ltd, Cascade Die Casting Group In, Buhler AG, MAGNIUM AUSTRALIA, Dongguan Minghe Die Casting Company, HARROP ENGINEERING, Kemlows Diecasting Products Ltd.

3. What are the main segments of the Australia Automotive Parts Magnesium Die Casting Market?

The market segments include Production Process Type, Application Type.

4. Can you provide details about the market size?

The market size is estimated to be USD 7.26 billion as of 2022.

5. What are some drivers contributing to market growth?

Automotive Industry Continues to Witness Steady Growth in Vehicle Production; Growing Awareness of Air Pollution and Health Concerns.

6. What are the notable trends driving market growth?

Pressure Die Casting Process dominating the market.

7. Are there any restraints impacting market growth?

Shift towards Disposable Filters.

8. Can you provide examples of recent developments in the market?

July 2022: Magnium Australia developed manufacturing technology that enable Australia to take advantage of a USD 300 billion magnesium export opportunity.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Australia Automotive Parts Magnesium Die Casting Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Australia Automotive Parts Magnesium Die Casting Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Australia Automotive Parts Magnesium Die Casting Market?

To stay informed about further developments, trends, and reports in the Australia Automotive Parts Magnesium Die Casting Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence