Key Insights

The India Foundry Market, valued at ₹19.46 billion in 2025, is poised for robust growth, exhibiting a Compound Annual Growth Rate (CAGR) of 10.30% from 2025 to 2033. This expansion is driven by several key factors. The burgeoning automotive industry, particularly the growth in domestic vehicle production and rising demand for commercial vehicles, significantly fuels the market. Increased infrastructure development initiatives across India, including construction of roads, bridges, and buildings, further boosts demand for cast iron and steel components. Furthermore, the expanding manufacturing sector, coupled with government initiatives promoting "Make in India," creates a favorable environment for foundry growth. The adoption of advanced technologies like 3D printing and digitalization in foundry processes is expected to contribute to increased efficiency and productivity, enhancing market prospects. While challenges such as fluctuating raw material prices and stringent environmental regulations exist, the overall growth trajectory remains positive.

India Foundry Market Market Size (In Billion)

Competitive intensity is evident, with prominent players like A Cast Foundry, Aditya Birla Management Corp Pvt Ltd, Brakes India Pvt Ltd, and JSW Steel Ltd vying for market share. The market is segmented based on product type (grey iron castings, ductile iron castings, etc.), application (automotive, construction, machinery, etc.), and region. While precise segmental data is unavailable, the automotive and infrastructure sectors are likely to dominate. Future growth hinges on sustained investment in modernization, technological advancements, and effective regulatory compliance by foundry businesses. The market's potential to reach significant heights in the coming years relies on continued government support and the ongoing expansion of India's manufacturing and infrastructure sectors.

India Foundry Market Company Market Share

India Foundry Market Report: 2019-2033

This comprehensive report provides an in-depth analysis of the India Foundry Market, offering invaluable insights for industry professionals, investors, and strategic decision-makers. With a study period spanning 2019-2033, a base year of 2025, and a forecast period of 2025-2033, this report delivers a clear understanding of the market's past performance, present state, and future trajectory. The report covers key segments, leading players, and emerging trends, empowering you to make informed decisions in this dynamic market. The market size is projected at xx Million in 2025.

India Foundry Market Structure & Innovation Trends

The Indian foundry market exhibits a moderately concentrated structure, with a few large players holding significant market share, while numerous smaller companies cater to niche segments. The market share distribution amongst the top 5 players is estimated at 40%, indicating opportunities for both growth and consolidation. Innovation is driven primarily by the increasing demand for lightweight, high-strength castings across various sectors, coupled with government initiatives promoting domestic manufacturing. Regulatory frameworks, particularly concerning environmental standards and safety regulations, play a crucial role in shaping industry practices. Product substitutes, such as plastics and composites, present a competitive challenge, particularly in certain applications. End-user demographics are broad, encompassing automotive, construction, machinery, and aerospace sectors.

M&A activity has been notable, reflecting the pursuit of scale, technological capabilities, and market access. Recent deals include:

- September 2023: Kirloskar Ferrous Industries Limited's acquisition of Oliver Engineering Pvt. Ltd. This acquisition adds 28,000 MT of annual casting capacity to KFIL. The deal value is not publicly disclosed.

- January 2023: Bharat Forge Ltd's subsidiary, J S Auto Cast Foundry India Private Ltd., acquired Indo Shell Mould Ltd.'s SEZ unit. The deal value was not disclosed.

Further analysis reveals that the average deal value for M&A transactions in the Indian foundry market between 2019 and 2024 was approximately xx Million.

India Foundry Market Dynamics & Trends

The India Foundry Market is experiencing robust growth, driven by factors such as rapid industrialization, increasing infrastructure development, and the booming automotive sector. The market is projected to witness a Compound Annual Growth Rate (CAGR) of xx% during the forecast period (2025-2033). Technological disruptions, including the adoption of additive manufacturing (3D printing) and advanced casting techniques like investment casting, are reshaping the industry. Consumer preferences are shifting towards lighter, more durable, and cost-effective castings. Competitive dynamics are characterized by intense price competition, coupled with a focus on product differentiation and technological innovation. Market penetration of advanced casting technologies is estimated at 15% in 2025, projected to increase to xx% by 2033.

Dominant Regions & Segments in India Foundry Market

The automotive sector remains the dominant segment, accounting for approximately xx% of the total market value in 2025. The state of Tamil Nadu is currently the leading region for foundry activity, driven by a strong automotive manufacturing base and supportive infrastructure. However, other states such as Gujarat and Maharashtra are also witnessing significant growth.

- Key Drivers in Tamil Nadu:

- Established automotive manufacturing clusters

- Availability of skilled labor

- Supportive government policies

- Well-developed infrastructure

Detailed analysis indicates that Tamil Nadu's dominance is likely to continue, driven by increasing investments in automotive manufacturing and the expansion of existing facilities. However, Gujarat and Maharashtra are expected to witness faster growth rates, driven by government initiatives and infrastructure investments aimed at attracting manufacturing companies.

India Foundry Market Product Innovations

Recent product innovations focus on developing high-strength, lightweight alloys for applications in the automotive and aerospace sectors. Investment casting and 3D printing technologies are being increasingly adopted to enhance product precision and reduce lead times. These innovations are gaining market acceptance due to their improved performance characteristics and cost-effectiveness. The adoption of Industry 4.0 technologies, such as automation and data analytics, is driving efficiency gains across the value chain.

Report Scope & Segmentation Analysis

This report segments the Indian foundry market based on material type (ferrous and non-ferrous), casting process (sand casting, investment casting, die casting, etc.), end-use industry (automotive, construction, machinery, etc.), and region. Each segment's growth projections and competitive dynamics are comprehensively analyzed. The ferrous segment currently holds the largest market share, but the non-ferrous segment is witnessing faster growth driven by increasing demand from the electronics and aerospace industries.

Key Drivers of India Foundry Market Growth

The growth of the India Foundry Market is primarily driven by several key factors: The burgeoning automotive industry, characterized by increased production of vehicles, fuels significant demand for castings. Government initiatives promoting infrastructure development, including smart cities and transportation projects, generate substantial demand. The growing demand for durable goods and industrial machinery creates opportunities across various sectors. Technological advancements, particularly in material science and casting processes, enhance product quality and efficiency. The increasing adoption of automation and Industry 4.0 technologies improves productivity and reduces costs.

Challenges in the India Foundry Market Sector

The Indian foundry sector faces challenges such as stringent environmental regulations leading to higher compliance costs. Fluctuating raw material prices impact profitability, and supply chain disruptions can affect production. Intense competition from both domestic and international players necessitates continuous innovation and cost optimization. The skilled labor shortage impacts productivity and operational efficiency. These factors collectively affect the industry's growth trajectory and necessitate strategic adaptations.

Emerging Opportunities in India Foundry Market

Emerging opportunities include the growing demand for lightweight castings in the automotive and aerospace industries. The adoption of additive manufacturing (3D printing) offers opportunities for customization and rapid prototyping. The expansion of the renewable energy sector creates demand for specific casting solutions for wind turbines and solar panels. Government initiatives focusing on "Make in India" stimulate domestic manufacturing and attract investments. These factors collectively contribute to the market's potential for future growth.

Leading Players in the India Foundry Market Market

- A Cast Foundry

- Aditya Birla Management Corp Pvt Ltd

- Brakes India Pvt Ltd

- CALMET

- JSW STEEL Ltd

- Larsen and Toubro Ltd

- Ashok Iron Works Pvt Ltd

- Gujarat Metal Cast Industries Pvt Ltd

- Electrosteel Castings Ltd

- Menon and Menod Ltd

- List Not Exhaustive

Key Developments in India Foundry Market Industry

- September 2023: Kirloskar Ferrous Industries Limited (KFIL) acquired Oliver Engineering Pvt. Ltd., expanding its casting capacity by 28,000 MT per annum.

- February 2023: Hindustan Aeronautics Limited and Bharat Forge Limited signed an MoU for developing aerospace-grade steel alloys, indicating a push towards high-value casting solutions.

- January 2023: Bharat Forge Ltd's subsidiary acquired Indo Shell Mould Ltd.'s SEZ unit, strengthening its presence in the casting sector.

Future Outlook for India Foundry Market Market

The India Foundry Market is poised for continued growth, driven by robust demand from key sectors and technological advancements. Strategic opportunities lie in adopting advanced manufacturing technologies, expanding into high-value segments, and focusing on sustainable and environmentally friendly practices. The market's growth will be further influenced by government policies and global economic conditions. However, the overall outlook remains positive, suggesting significant potential for growth and investment in the coming years.

India Foundry Market Segmentation

-

1. End-user

- 1.1. Automotive

- 1.2. Electrical and Construction

- 1.3. Industrial Machinery

- 1.4. Other End-Users

-

2. Type

- 2.1. Gray Iron Casting

- 2.2. Non-ferrous Casting

- 2.3. Ductile Iron Casting

- 2.4. Steel Casting

- 2.5. Malleable Casting

India Foundry Market Segmentation By Geography

- 1. India

India Foundry Market Regional Market Share

Geographic Coverage of India Foundry Market

India Foundry Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 10.30% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. 4.; Increasing Focus on Technology Upgrades4.; Formation of Foundry Clusters

- 3.3. Market Restrains

- 3.3.1. 4.; Increasing Focus on Technology Upgrades4.; Formation of Foundry Clusters

- 3.4. Market Trends

- 3.4.1. Growing Automobile Sector is Driving the Foundry Market in India

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. India Foundry Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by End-user

- 5.1.1. Automotive

- 5.1.2. Electrical and Construction

- 5.1.3. Industrial Machinery

- 5.1.4. Other End-Users

- 5.2. Market Analysis, Insights and Forecast - by Type

- 5.2.1. Gray Iron Casting

- 5.2.2. Non-ferrous Casting

- 5.2.3. Ductile Iron Casting

- 5.2.4. Steel Casting

- 5.2.5. Malleable Casting

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. India

- 5.1. Market Analysis, Insights and Forecast - by End-user

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2025

- 6.2. Company Profiles

- 6.2.1 A Cast Foundry

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Aditya Birla Management Corp Pvt Ltd

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Brakes India Pvt Ltd

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 CALMET

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 JSW STEEL Ltd

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Larsen and Toubro Ltd

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 Ashok Iron Works Pvt Ltd

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Gujarat Metal Cast Industries Pvt Ltd

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Electrosteel Castings Ltd

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 Menon and Menod Ltd **List Not Exhaustive

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.1 A Cast Foundry

List of Figures

- Figure 1: India Foundry Market Revenue Breakdown (Million, %) by Product 2025 & 2033

- Figure 2: India Foundry Market Share (%) by Company 2025

List of Tables

- Table 1: India Foundry Market Revenue Million Forecast, by End-user 2020 & 2033

- Table 2: India Foundry Market Volume Billion Forecast, by End-user 2020 & 2033

- Table 3: India Foundry Market Revenue Million Forecast, by Type 2020 & 2033

- Table 4: India Foundry Market Volume Billion Forecast, by Type 2020 & 2033

- Table 5: India Foundry Market Revenue Million Forecast, by Region 2020 & 2033

- Table 6: India Foundry Market Volume Billion Forecast, by Region 2020 & 2033

- Table 7: India Foundry Market Revenue Million Forecast, by End-user 2020 & 2033

- Table 8: India Foundry Market Volume Billion Forecast, by End-user 2020 & 2033

- Table 9: India Foundry Market Revenue Million Forecast, by Type 2020 & 2033

- Table 10: India Foundry Market Volume Billion Forecast, by Type 2020 & 2033

- Table 11: India Foundry Market Revenue Million Forecast, by Country 2020 & 2033

- Table 12: India Foundry Market Volume Billion Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the India Foundry Market?

The projected CAGR is approximately 10.30%.

2. Which companies are prominent players in the India Foundry Market?

Key companies in the market include A Cast Foundry, Aditya Birla Management Corp Pvt Ltd, Brakes India Pvt Ltd, CALMET, JSW STEEL Ltd, Larsen and Toubro Ltd, Ashok Iron Works Pvt Ltd, Gujarat Metal Cast Industries Pvt Ltd, Electrosteel Castings Ltd, Menon and Menod Ltd **List Not Exhaustive.

3. What are the main segments of the India Foundry Market?

The market segments include End-user, Type.

4. Can you provide details about the market size?

The market size is estimated to be USD 19.46 Million as of 2022.

5. What are some drivers contributing to market growth?

4.; Increasing Focus on Technology Upgrades4.; Formation of Foundry Clusters.

6. What are the notable trends driving market growth?

Growing Automobile Sector is Driving the Foundry Market in India.

7. Are there any restraints impacting market growth?

4.; Increasing Focus on Technology Upgrades4.; Formation of Foundry Clusters.

8. Can you provide examples of recent developments in the market?

September 2023: Kirloskar Ferrous Industries Limited (KFIL), one of the leading castings and pig iron manufacturers in India, announced the acquisition of Oliver Engineering Pvt. Ltd. Oliver Engineering is engaged in the business of ferrous casting and machining with its manufacturing facility located in Village Sandharsi, Tehsil Rajpura, State Punjab. Its present castings capacity is 28,000 MT per annum. KFIL also produces various grades of pig iron such as SG iron grade, basic steel grade, and foundry grade.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million and volume, measured in Billion.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "India Foundry Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the India Foundry Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the India Foundry Market?

To stay informed about further developments, trends, and reports in the India Foundry Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

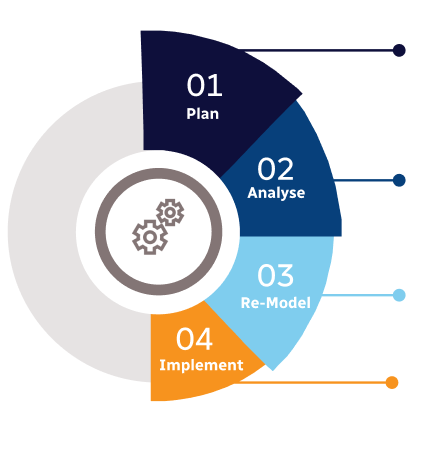

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence